Winding: Coil is aproximately 30 turns, No. 28 Awg. Either wound in a round shape, square or in a rectangle! A Diameter of about 6 to 8 inches is about normal. In a Rectangle, Optimum is about a 4 to 1 ratio, length to width. I Recommend having Inductance Values between 300 to 400uH.

Some guys using my detector have wound coils up to 4 Feet Square for deep searches of large objects! These large coils are usually only 6 turns or so!

Each has its advantages and disadvantages! Also more turns and bigger wire equils a greater magnetic field. But don't go overboard. Even very small coils of a "1 inch" diameter can be useful!

Low Capacitance is important in the coils. This can be further acomplished by winding the coil in a single layer spiral. It's not too easy to do, but it can be done and will make your unit much better.

Some tests that I have done on wires in the 22AWG to 18AWG range:

1) Two parallel wires, close together, 1 foot long 18AWG = 42 Pf.

2) Two parallel wires, close together, 1 foot long 20AWG = 39 Pf.

3) Two parallel wires, close together, 1 foot long 22AWG = 36 Pf.

These tests were done at a frequency of 1000 Hz.

This Only affects Direct Parallel Wires, But does not affect Coils in the same manner.

However, Inter-wire Capacitance can greatly reduce the effectiveness of the coil!

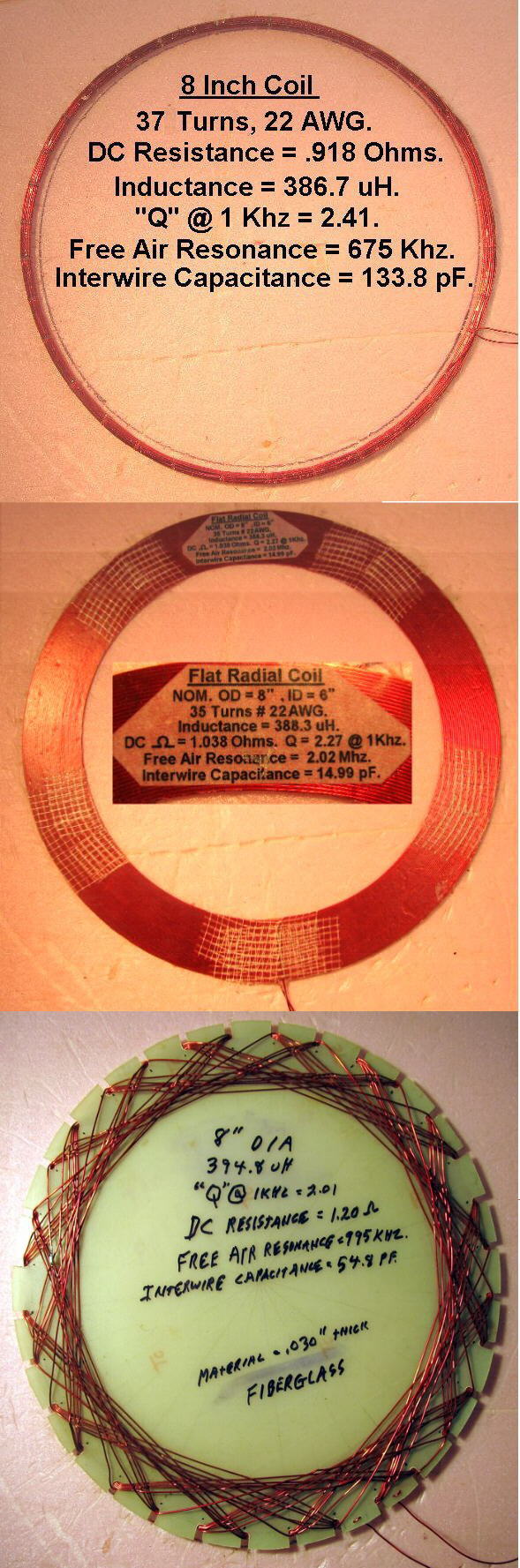

All having Simular Inductance Values.

Top Coil, Just Scramble Wound and Epoxy Coated.

Middle Coil, My Typical "Flat Wound Coil", Epoxy Coated.

Bottom Coil, Attempting to reduce Interwire Capacitance, Not Coated.

NOTE:

The "Interwire Capacitance" and "Free Air Resonance" of each of these coils.

Finishing PI Coils: After you are happy with the coil, it is important to make it somewhat RIGID. Possibly a Light Epoxy Coating. Do NOT Go Excessive with this, as Too Much can also Deter Performance. But Small amounts of movement within the coil can somewhat affect performance!

Also make sure the Wire leads coming from the coil, go out horizontal, Not directly Above or below the coil!

Dual Coil, Cancelling Design

Two coils have the advantage of "Noise Rejection" should their be unwanted interferance in the vacinity of your search! One coil does the search, While the other coil cancels noise and simular signals. Particularly useful if it is to be used near Power Lines or soil containing a lot of iron deposits!

If two coils are used, they are easiest done Round or a "D" Shape. Wind both Round Coils identical and overlap them up to about 50%, but not greater than. For "D" Shaped Coils, just use a 1/2 to 1" overlap on the Flat Sides of the D. Keep both wound in same direction when overlapped! The Less the overlap or no overlap, will results in a smaller confined field of search, covering less area. "Ideally these Coils should be Nulled with the use of an Oscilloscope".

Follow the Winding and Finishing Instructions for the Single Coil as well as the info here that is related specificially to the Two Coils!

Dual Coils, Seperate Recieve & Transmit

This Coil Configuration allows the transmit coil to be constructed for maximum magnetic field with a fairly heavy wire, while using a recieve coil with more turns of smaller wire for better pickup. But it can be somewhat Tricky to make this work good.

All Imformation in this Article is "Copyright protected".

Chemelec

*Copyright © 2003 & 2015*